- Fuel Pressure Regulator

- |

- Electrical Actuators

- |

- Repair Basics

- |

- Technical Info

- |

- Car Tech Info

- |

- MicroTronik

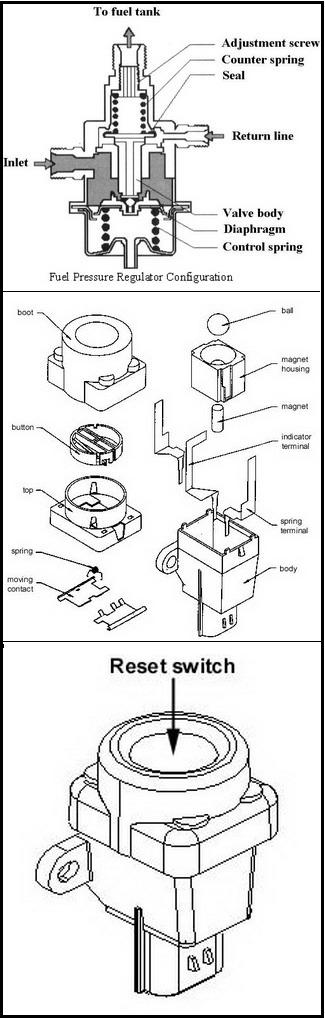

Fuel Pressure Regulator

Fuel Pressure Regulator Config

Fuel Pressure Regulator work

1) Function

Injection rate through injector depends on injection pressure, injection time and orifice size. Therefore in order to control fuel injection rate by means of current connecting time for an injector with spray hole size fixed, injection pressure shall remain constant for any varied pressure at intake manifold.Fuel injection rate required by engine is controlled by power supply time of the injector from ECM. At a given power supply time as fuel pressure is not controlled, even if power time of the injector is the same, if fuel pressure is high fuel injection rate will be high and if the pressure is low the rate will be low.

Injection occurs at intake manifold. At a given fuel pressure against atmospheric pressure, when absolute pressure of the intake manifold is low, fuel injection rate will be high, and when the pressure is high the rate will be low. Therefore fuel pressure regulator maintains fuel pressure always higher than intake manifold pressure base of the injection pressure, by a certain level as pre-set, so as to enable to control injection rate only by injector power supply time.

Therefore fuel pressure regulator regulates injection pressure of the injector at a certain level against negative pressure of the intake manifold.

2) Configuration and Operating Principle

Pressure regulator consists of outer metal housing, valve diaphragm and diaphragm chamber, and fuel chamber.Diaphragm chamber is connected with surge tank via vacuum hose and therefore has negative pressure from intake manifold. When fuel pressure is over specified value, diaphragm will be raised by vacuum from surge tank, and surplus fuel will return through return pipe to fuel tank. For example, at diaphragm pressure is set at 3.35kg/cm2, when intake manifold negative pressure is 0 and fuel pressure is above 3.35kg/cm2, the pressure will disable the spring tension and push diaphragm up to return surplus fuel to fuel tank.

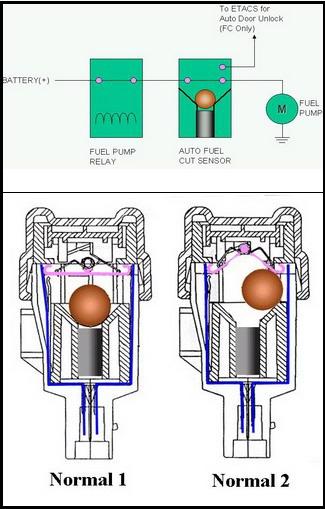

1) Auto Fuel Cut System

Auto fuel cut system is a safety device to prevent the fire when the vehicle is crashed. It cuts the electrical power of the fuel pump if the sensor detects the crash.The sensor location is on the left hand side strut housing in the engine room.

Operation range:

Over 25 Km/hour

Front crash:

Must be switched off 22 Km/hour - 14 Km/hour.

Gray zone:

under 12 Km/hour front crash: must not be switched off

If the vehicle is crashed, steel ball is moved up. The steel ball pushes the (moving contact), the switch is turned off.

Service point

Reset the sensor by pushing of reset switch when the sensor is replaced. Reset the sensor to start the engine after crash. Engine does not start if the sensor was not reset.

Component inspection two terminals should be continued after reset.

You can check the actuator actual value and status and activate it when it is possible by AutoHex auto Diagnostic Scanner under the supported car brand and according to engine type.

Changing Dmaged DME in F Series

Description

Injection rate through injector depends on injection pressure, injection time and orifice size. Therefore in order to control fuel injection rate by means of current connecting time for an injector with spray hole size fixed, injection pressure shall remain constant for any varied pressure at intake manifold.

Autohex II Reviews

AutoHex II

AutoHex II is your best choice to have full access to dealer functions like coding, adjusting and modules flashing/programming, Contact us for prices

AutoHex Forum