Vehicle Fuel Pump

Fuel Pump types

Fuel systems types

1. Fuel Pump Outline

Upon starting, fuel pump is driven by battery power and controlled by ECM, thereafter. Tube types of fuel pumps are used: Pumps of in-tank type are installed in fuel tank and pumps of in-line type are installed outside fuel tank. In-line type pumps are generally preferred and used due to their superior anti-noise and anti-vapor-lock characteristics. The pump consists of a DC motor, a check valve, and a relief valve, and has relatively high current that is controlled by control relay, etc.In accordance with installation methods, the pumps are divided into:

- External fuel pump.

- In-tank fuel pump.

2. External Fuel Pump

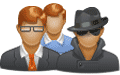

An external fuel pump is a fuel pump installed in line outside fuel tank that sucks fuel by means of centrifugal force generated by the rotating rotor of a ferrite-type motor, and provides the fuel to fuel supply line. Fuel pump consists of rotor plate that is driven by motor, pump casing eccentrically located against rotor plate, and roller that seals pump spacer between pump casing and rotor plate.Operation of fuel pump relies on the centrifugal force generated by rotor, that will push outer wall of pump spacer moving along the wall, in order to generate vacuum space between rollers and pump spacer at inlet side, and then the vacuum space will be filled with fuel. Rotation of the Roller will increase the space and deliver the fuel to outlet side. Then the space will be decrease at outlet side increasing pressure to discharge the fuel. Discharged fuel from the pump will then pass around the armature of the motor to open check valve and there after pass through silencer to reach fuel line. Suction/discharge will be completed by one revolution of rotor during pump operation.

Fuel pump has operation speed of 1,700-2,500 rpm, and discharge rate of about 1.5-2.5 l/min and pressure of 3.0~6.0.

Fuel line has supply pressure of 2.75-3.40 regulated by fuel pressure regulator and includes silencer at outlet side to prevent pulsation of pump.

1) Relief Valve (Pressure Limiter)

When fuel supply line is clogged during the pump operation, relief valve will ensure safety and avoid risk of damaging fuel supply system and fuel leak. The valve will open, if fuel pressure reaches specified value, in order to route the high pressure to the inlet side of the pump and then through the inside of pump and motor for preventing cumulative pressure.

2) Check Valve (Non-Return Valve)

Upon stopping engine, check valve located in fuel pump will close using spring force, and maintain pressure inside fuel line to ensure easier re-start of engine, and to prevent possible vapor lock by high temperature in fuel system.

3) Silencer

Silencer decreases the pressure change (pulsation) and noise generated by fuel flow from fuel pump, relying on diaphragm and orifice.

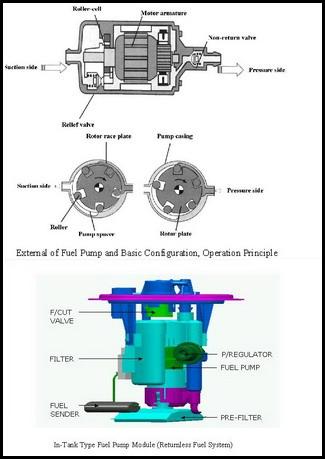

3. in-tank Fuel Pump

Most of in-tank fuel pumps are from impeller type. The pump is installed in fuel tank, and therefore superior to external fuel pumps in the following characteristics:- low operation noise and to less discharge pulsation of fuel.

- low torque and high revolution type motor enables compact and light design.

- Have great characteristics to prevent fuel leak and vapor Lock.

1) Relief Valve

Fuel pump operates by DC motor at constant speed, and therefore generates constant pressure of discharged fuel, irrespective to engine speed. The discharge pressure, however is set based on high-speed operation of engine, and then will rise too high when engine operates at low speed and consumes less oil. The abnormally high pressure will then open relief valve, in order to lower the pressure and maintain constant fuel pressure in fuel line that will otherwise go up abnormally higher than specified pressure value.

2) Check Valve

As soon as fuel pump stops check valve spring will automatically close outlet, in order to maintain fuel pressure in fuel line, and consequently prevent otherwise possible vapor lock in fuel line by high temperature during summer-time or after stopping engine, and ensure easier start-up of engine next time. In addition the valve prevents reverse flow of fuel due to excessive pressure in fuel line upon engine start-up

4. Operation Checking of Fuel Pump

1) Turn off ignition switch.2) Directly connect battery power to fuel pump drive connectors. Listen to the pump operation noise. As the pump is located inside fuel tank, you may be hard to hear the noise. Then open fuel tank cap and listen to the noise through filler port.

3) Install a pressure gauge at service valve or fitting surface of pressure gauge, and watch, rising fuel pressure. (See below for more details)

4) Use an ammeter and measure current consumption of fuel pump.

5) Hold fuel hose with hand check to feel the fuel pressure.

As for the fuel pump operation voltage, measure the voltage at the fuel pump check terminal in the engine cranking or engine running condition.

In this case, measured voltage should be the same as the battery voltage. If not, check the fuse, fuel pump relay, ECM and wiring condition of the fuel pump check terminal.

The ECM operates fuel pump when crankshaft position sensor transmits the signal. If the fuel pump, injector and ignition spark do not operate while cranking, check the crankshaft position sensor. As for the crankshaft position sensor check, please refer to the engine sensors section.

As for the fuel pressure check, measures the fuel pressure at the fuel line to check whether it meets specification or not. Please refer to the shop manual, because measurement location and fuel pressure varies with difference models.

5. Fuel Pressure Test

1) Fuel Pressure RegulatorFuel amount injected by an electronically controlled engine relies on fuel pressure and length of fuel injection time. Therefore the fuel quantity is controlled by length of fuel injection time under constant fuel injection pressure. Then pressure gap between fuel pressure and inside of intake manifold shall be constant in order to control fuel injection rate by the time of fuel injection of injector. For this purpose, fuel pressure regulator is installed in fuel delivery pipe (In case of returnless fuel system it is located with fuel pump inside of fuel tank). Fuel pressure regulator has spring seal, which is connected to intake manifold via vacuum hose effecting pressure variation in intake pipe in order to maintain the injection pressure constantly.

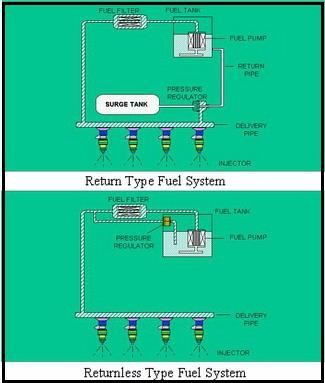

Fuel pump maintains fuel pressure approximately constant for right injection. Two types of fuel pump are available:

- Return type system returns surplus fuel except for supplying into engine.

- Returnless type system supplies fuel just as much as used for engine.

2) Returnless Fuel System

The advantage of Returnless type over return type is to constrain fuel temperature and vaporized gas generation as possible. When fuel is supplied to engine and returns, the fuel will be heated by engine and become hot, and therefore it is needed for fuel to supply only at quantity used for engine. Minimizing the fuel vapor is intended to respond to emission control regulation.

Return type pumps deliver always constant quantity of fuel, and easy for pressure control.

On the contrary Returnless type pumps would require a fuel pressure regulation mechanism. Pressure check valve is designed inside the pump to constrain the pressure at certain level when the pressure goes beyond the level. Besides length of injector opening time is used of micro-adjustment of fuel supply.

3) Fuel Pressure Test Procedure (Return Type Fuel System)

In order to release residual fuel pressure in fuel pipe line and prevent fuel from flowing out:

1) Disconnect fuel pump harness connector at fuel tank side.

2) Start engine, and leave it idling until stops for itself, and then turn ignition off.

3) Disconnect battery negative (-) terminal.

4) Connect fuel pump harness connector.

- Disconnect high pressure fuel hose at delivery side.

- Using a fuel pressure gauge adapter, install a fuel pressure gauge on fuel filter. Tighten it to the specified value.(tightening torque for fuel pressure gauge and fuel filter: ( 2.5~3.5kgm).

- Connect battery (-) terminal.

- Connect battery terminal/to drive terminal and operate fuel pump and then check matching face with pressure gauge and special tools for leak.

- Connect vacuum hose to pressure regulator, and measure fuel pressure again. (specified valve for fuel pressure: approx. ( 2.75kg/cm2).

- If the measurements are outside the specified values.

- Stop engine and watch movement of the pointer of the pressure gauge. The pointer shall not move. If the pointer moves down, check the moving range.

6. Symptoms of Fuel Pump Failure

- Stop the engine during idling.

- In driving, acceleration is poor and bumpy or engine goes out.

- Noise of fuel pump motor is high.

- Poor or non start-up of engine.

You can check the actuator actual value and status and activate it when it is possible by AutoHex automotive Scanner under the supported car brand and according to engine type.

BMW ECU Programming

Description

Fuel Pump is powerd from the Vehicle battry and connected to the engine ECU , to give the engine the fuel at the right pressure suitable for its work

Autohex II Reviews

AutoHex II

AutoHex II is your best choice to have full access to dealer functions like coding, adjusting and modules flashing/programming, Contact us for prices

AutoHex Forum